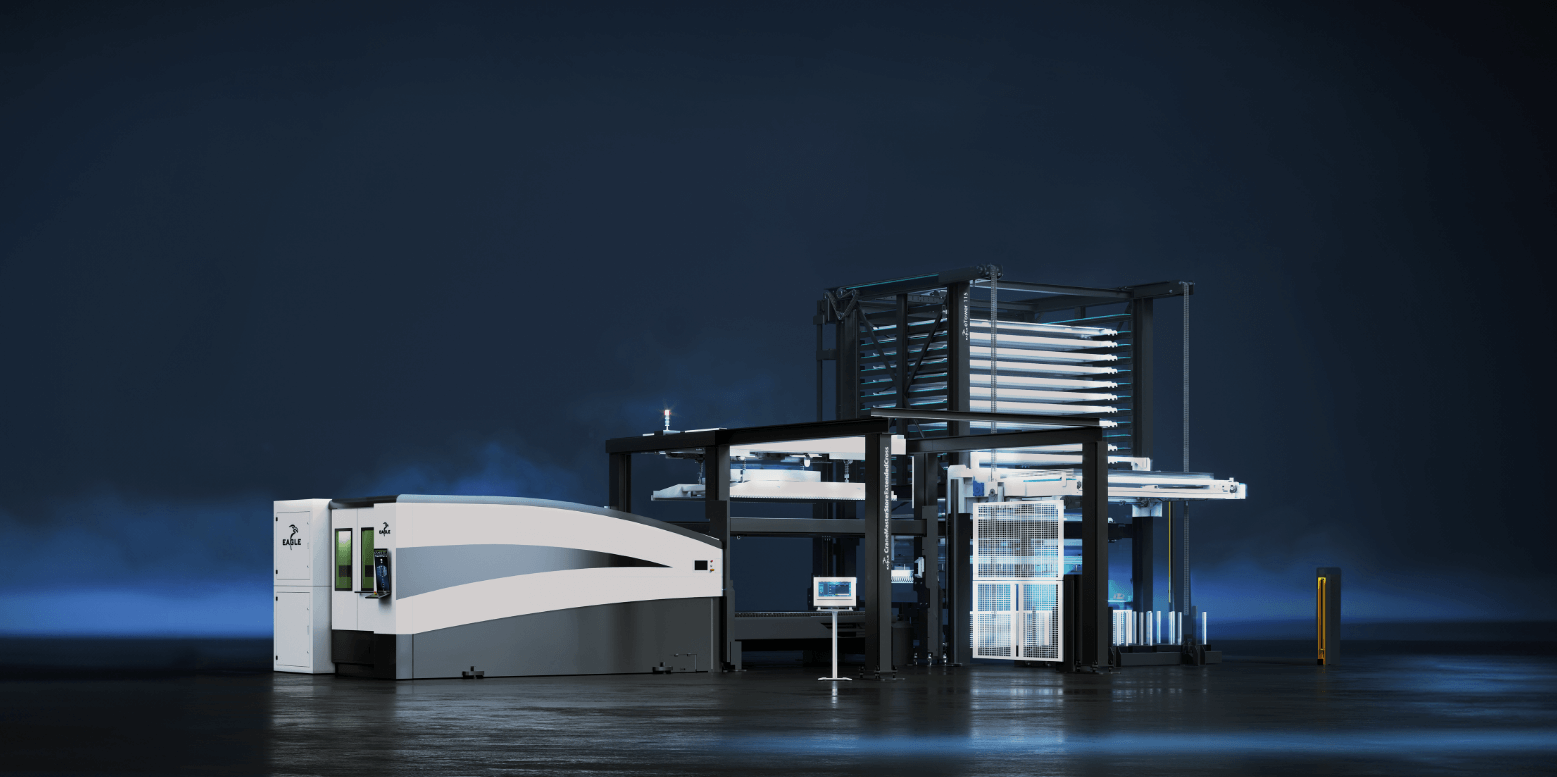

Boost your productivity with Eagle Automation

A high-performing machine can only reach its true potential when paired with material handling automation. We offer solutions that seamlessly integrate with our machines’ capabilities

A COMPLETE SOLUTION FOR material handling automation.

The 5 BENEFITS

of Eagle

Automation

-

1. High Efficiency

Streamlined material allowing users to fully exploit the machine's speed and achieve higher energy efficiency.

-

2. High Flexibility

Flexible setups that can be duplicated and extended according to each client’s needs making the best use of floor space.

-

3. High Autonomy

Material handling automation allows for uninterrupted production without supervision, even during night shifts and weekends.

-

4. High Safety

Additional conveyor belt for safer part retrieval, anti-scratch brushes, non-invasive sheet thickness measurement, and individual suction cup adjustments.

-

5. High Integration

Seamless integration with our laser cutting machines’ capabilities for flawless functioning from day one.

Explore our automation solutions

Our proprietary automation systems are the perfect fit to fully exploit our machines’ capabilities. What our machines can cut, our automation can handle. With versatility, modularity and ergonomics at their core, Eagle material handling automation solutions can perfectly adapt to your business’ needs, making the most of floor space and taking efficiency to the next level.

Watch our automation in action

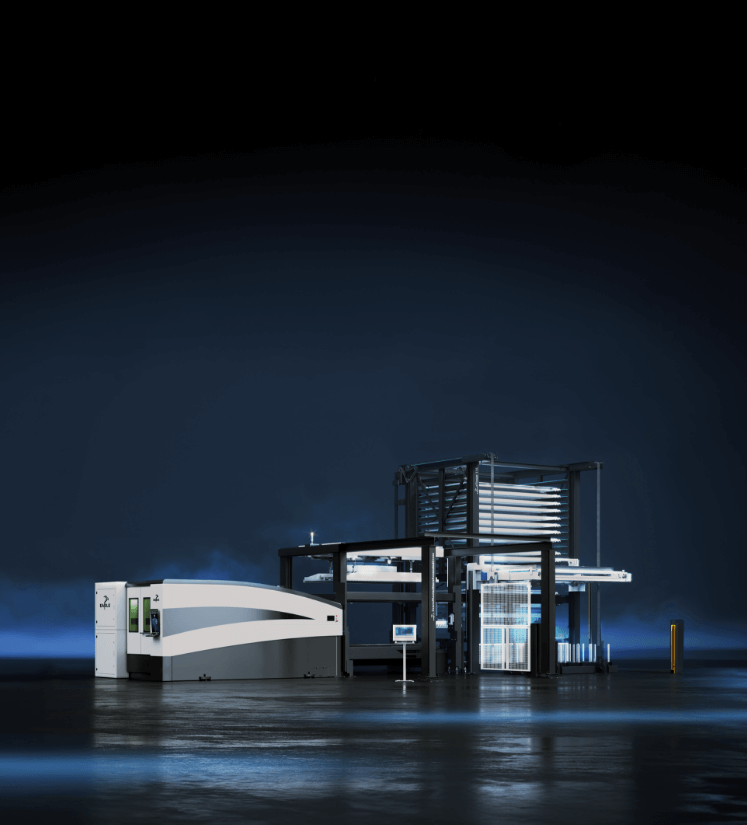

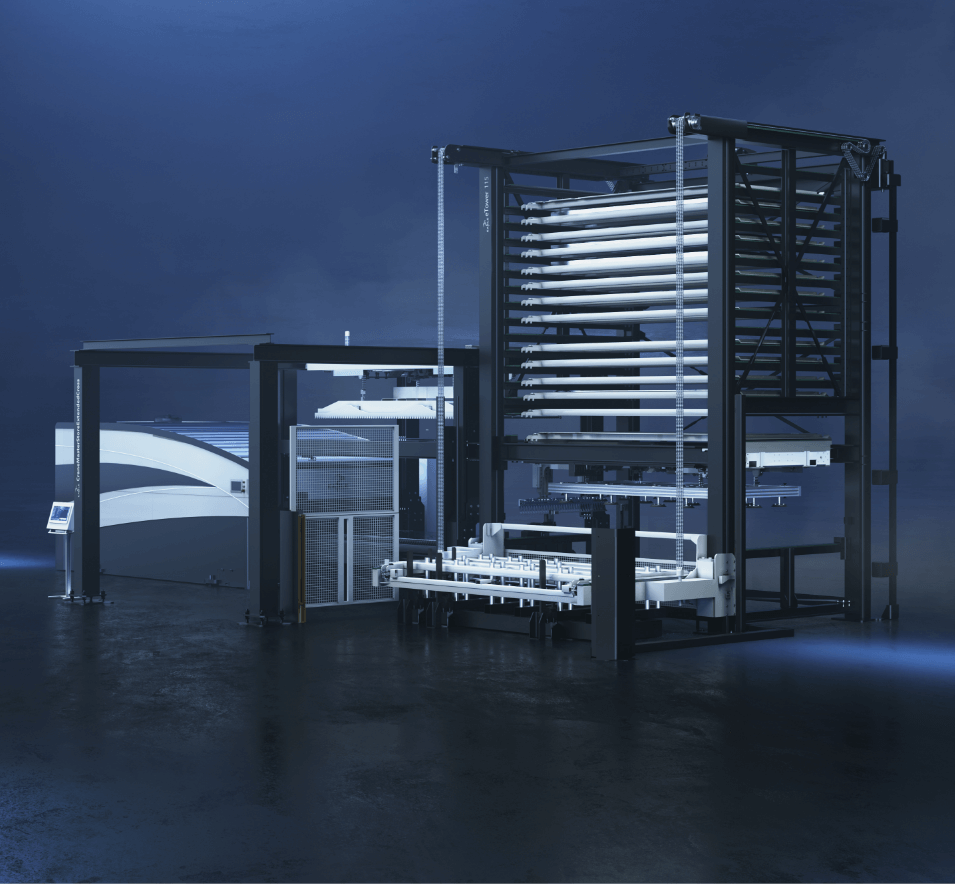

Watch the CraneMasterStore alongside the eTower110 material handling automation system at work. Thanks to this solution, material can be efficiently loaded from storage towers onto the cutting table whilst simultaneously unloading and storing cut parts.

Here we see the eTower110 and the CraneMasterStoreLinear which is the most flexible of the CraneMaster family. The loading/unloading stations can be positioned on either side of the machine, and pallets can be set on the floor rather than on a special table.