Take your productivity to the next level with the most efficient sheet metal cutting technology on the market

PIONEERS IN SHEET METAL CUTTING technology since 2006

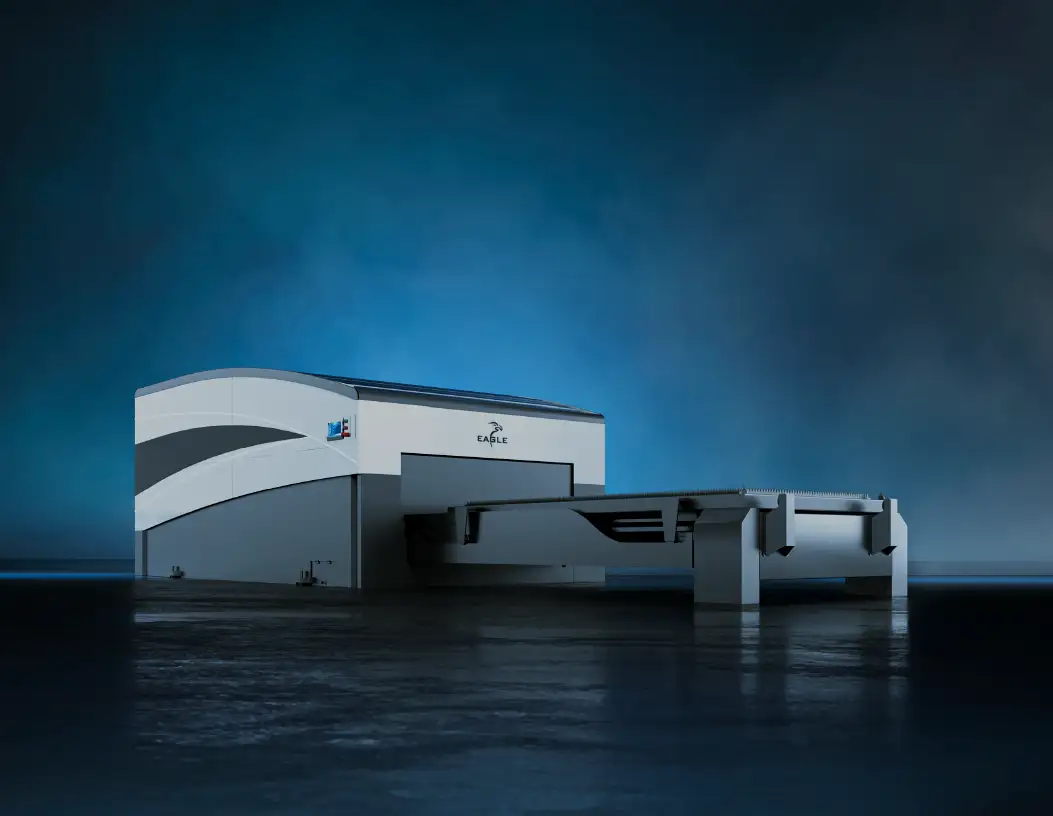

Eagle is a high-tech R&D company specializing in fiber laser technology and automation solutions for sheet metal cutting.

With innovation at our core, we build our systems following the “Ideal Machine Concept”, distilling every function to its essence to provide the highest efficiency, productivity and reliability with minimum maintenance needs. We manufacture 80% of our components in-house. This allows us to design each element for a perfect fit and maximum performance while retaining the autonomy for further development.

Our unique approach from concept to construction has positioned us among the leading providers of high-performance fiber laser cutting systems worldwide.

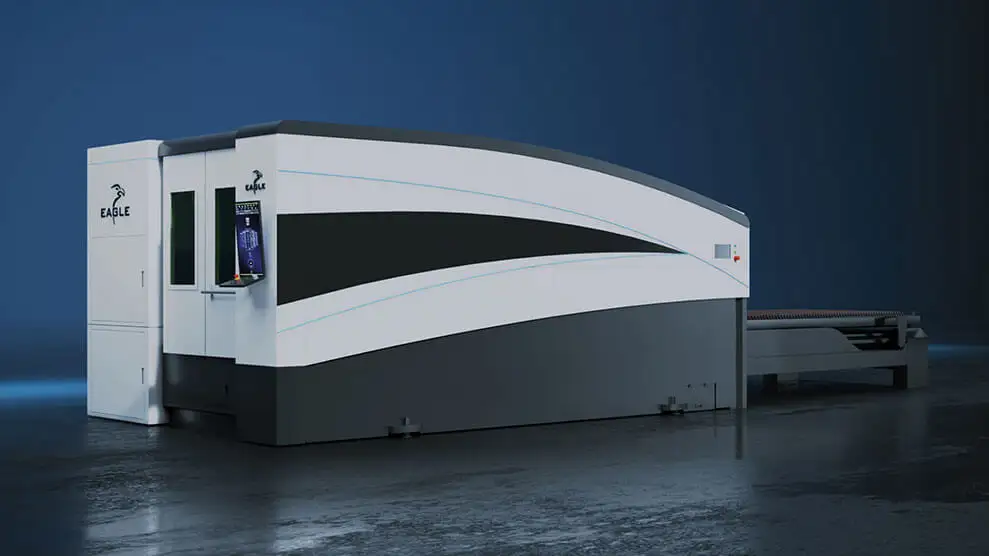

LASER CUTTING MACHINES

Our sheet metal cutting technology is designed to suit every production need. With powers ranging from 4kW to 40kW and maximum accelerations of up to 2G, 3G and 6G, all our fiber laser cutting machines are built with the highest quality standards and a human-centric approach to enhance productivity and workflow.

Explore all our machine series

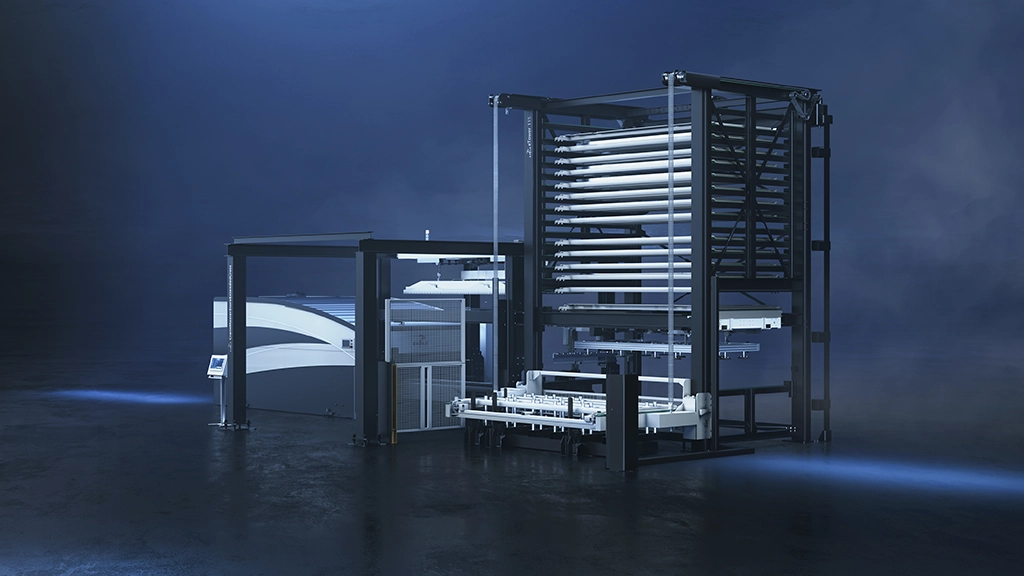

AUTOMATION SOLUTIONS

Our proprietary automation systems are the perfect fit to fully exploit our machines’ capabilities. With versatility, modularity and ergonomics at their core, we offer a complete solution for automated material handling making the most of floor space and taking productivity to the next level.

Find out moreExplore our product portfolio

THE ADVANTAGES OF HIGH POWER AND ACCELERATION

Higher power and acceleration are key to fully exploit fiber laser technology resulting in the highest sheet metal cutting performance and providing you with invaluable benefits:

- Enhanced overall efficiency

- Reduced energy consumption

- Reduced use of gas and all consumables

- Reduced piercing time

- Lower cost per part

- Higher profit per part

- Higher return of investment

Find out how to increase your production efficiency with Eagle technlology

REQUEST A FREE QUOTATIONWatch the impact of high performance with your own eyes

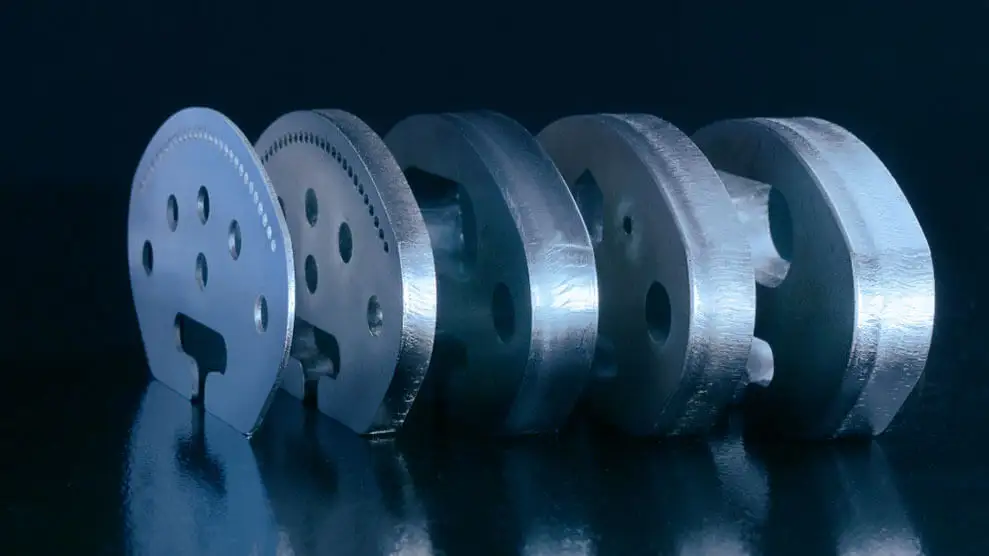

THE IMPACT OF POWER

When dealing with thicker materials, high powers have a huge impact in cutting speed and efficiency. Here, the same Eagle iNspire machine cuts 15mm mild steel at different powers ranging from 15kW to 40kW for an exponential increase in productivity.